A lot of news and progress to share in this latest newsletter issue, #38 - November 2017. A replacement boiler has been sourced for steam locomotive Ab 745, which arrived at Maymorn on 13 October 2017, and immediately swapped onto the locomotive frames for storage inside the shed. We're grateful to Rimutaka Trust and the Community Trust of Wellington for funding the remaining purchase cost and transport of the boiler.

There's a lot of progress to report on at the railway, from concrete floors and steps within the shed, through to workshop linings, track improvements, work on our ballast wagon fleet, engine hood frame for diesel loco ORB #1, and fabrication of a regulator and new cabs for steam locomotives Wb 292 and 299.

During Summer 2017/2018 we're also planning on extending our mainline track out past the pedestrian crossing, to a point opposite the Metlink passenger station.

We thank Ben Calcott for the work put into the railway, stepping down as Chairperson mid-year. We congratulate and thank Iain Palmer on his appointment as Deputy Chairperson and Operations Manager, Ray Hampton to Rail Vehicle Manager, and Hugh McCracken as Chairperson.

A big thank you to all our Trustees, members and supporters for the work and funding put into the railway, and we look forward to your continued support.

Hugh McCracken, Chairperson

Replacement boiler for Ab 745

After months of planning and fundraising, a replacement boiler has been secured for steam locomotive Ab 745. It was originally secured by the New Zealand Railway and Locomotive Society (NZRLS) as a spare boiler for Ab 608 or Wab 794, purchased surplus to requirements from a market garden in Canterbury.

The Trust purchased the boiler from NZRLS as-is-where is at Feilding earlier in 2017.

During the second week of October the boiler was transported from Feilding to Maymorn, and swapped onto the engine frame of Ab 745 on Friday 13 October.

Many thanks to Rimutaka Trust for funds to complete the purchase of the replacement boiler, and Community Trust of Wellington for funding the transport and initial conservation work.

Work in progress - October 2017

A selection of photos of work in progress around the railway.

Promotions

We had the Wb cab display at the Upper Hutt Summer Carnival at the end of February 2017, which was lifted in and out by hiab truck. An alternative display was worked up for March Madness.

A backlog of tasks have been done in recent months, lifting the standard of the railway and finishing off some minor work remaining on some of our track structures.

Concrete floor and steps have been prepared and poured, improving under foot conditions in the rail vehicle shed. Insulation and internal lining work is moving along in the workshop, with half of one end wall nearing completion, and a start made on the ceiling.

Progress has been made with cabs for both Wb 292 and Wb 299.

The lining work inside the workshop has moved along during winter and spring 2017. A modest amount of ColorSteel cladding was ordered to continue the work, opting for a lighter "Titania" colour to keep the workshop interior reasonably light. There is a lot of fitting up and flashing work to do, but good progress has been made in the past few weeks.

We welcome contributions towards this work, and are seeking funding to help purchase the next orders of cladding.

Ballast wagon restoration total reaches six

In September work started on repairing and restoring a sixth ballast wagon - Yc877. The ongoing programme of work is lifting the overall presentation and standard of the 13-strong fleet. The hopper, underframe and running gear receive attention, and care is taken to clean down and paint the hard-to-reach areas.

Engine hood frame repairs for ORB No.1

A new engine hood frame is being fabricated for the railway's 30-tonne diesel shunt locomotive - former Ohai Railway Board No.1. The original hood frame had rusted beyond viable repair during its many years outside, exacerbated by build-up of coal dust during the course of its work, and contact with aluminium engine hood doors.

Regulator for Wb 299

A regulator handle is being manufactured in Canada for Baldwin steam loco Wb 299, adding key components to the rebuild of the 1898-vintage locomotive.

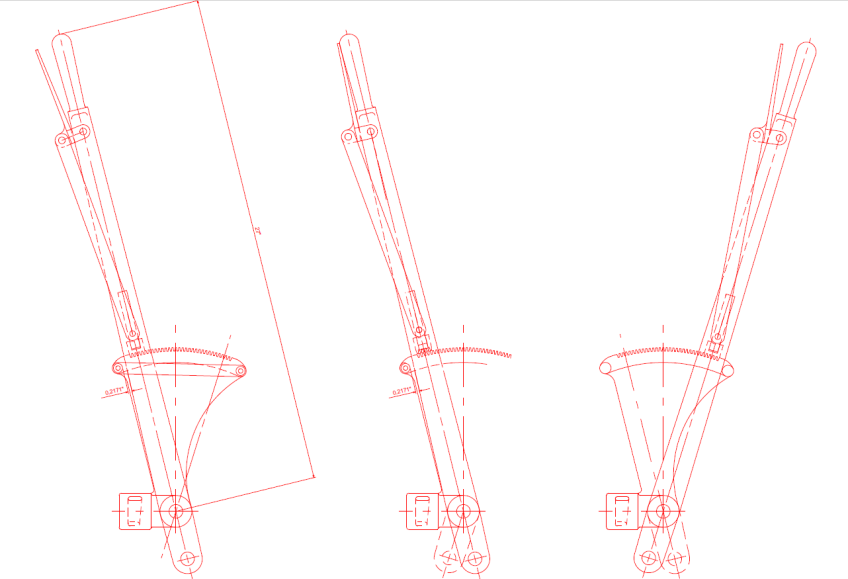

Trust member Peter Darian-Varzeliotis prepared CAD drawings for the various components that are mounted on the boiler back-head, including the regulator handle and clasp, latch and connecting rod and the sector plate. The latter, with its many fine-pitched teeth, presented a design challenge as details in the blueprint were unclear.

The dimensions of the hand-drawn teeth were inconsistent, so reference was made to a sample sector plate for these dimensions. Cross-reference was made to NZR Wb class boiler drawing - y7508 - listed BP 5213 for regulator gear, which was common between Wb and Wf locomotive classes, with further detail differences depending on the diameter of the regulator valve.

Work has just started on the regulator handle and the clasp that engages in the sector plate, as seen in the photos in this article. Our many thanks to Robin Teeling of Teeling Metal Specialties, Ontario, Canada for the work done on these components.

Once completed the components will be test fitted to the mounting on the boiler back-head confirming fit - or any final fitting work that might need to be done. We also plan to incorporate it as an interactive item into the Wb loco cab that is on display at Maymorn.

Our thanks again to Robin Teeling and Peter Darian-Varzeliotis for their work on these components.

Gumdigger carriage restoration starts

Work has started on the long-term project to restore 1884-vintage Gumdigger carriage A255 back into service. During the past year a conservation plan has been drafted, outlining the history of the carriage, detailing the fabric of the vehicle it its current state, and a project plan formed for its restoration.

In the first half of 2017 the interior of the carriage was cleaned out, cupboards and other non-railway items carefully removed. Roof ribs and other items found to be in reasonable order have been checked over and sanded back to sound timber. Most exterior tongue-and-groove cladding has been removed from the frame, much of it in poor condition due to ground contact. Steel roof sheets that protected the carriage from the elements has also been removed.

Next steps with the project are to raise funds for replacement timber beams that form the top and bottom plates. This would physically reunite the two halves of the carriage and enable the painstaking replacement of studs and other framing timbers.

Upper Hutt Summer Carnival 2017

Steam locomotive Wb 299 cab and interactive display was the centre-piece of our display at the 2017 Upper Hutt Summer Carnival. We rigged up a petrol-power air compressor to a pea-shooter whistle, which carnival goers were invited to try. The Pyle-National headlight and gauge lights could be worked as well, with light cast onto a steam pressure gauge and the original Baldwin Locomotive Works maker's plate that was fitted to Wb 292.